Products

Our High quality products

With over 300 moulds and more than 100 machines, it produces a wide array of plastic products by means of injection moulding, blow moulding, film blowing to manufacture plastic pallets, crates, cutleries, iml containers (with In Mould Labelled technology), shampoo bottles, chemical jerrycans ranging from 1 liter to 220 liters drums. Ld roll & bags ( FFS films, PE rolls, Shrink, Greenhouse rolls, Lamination films, range of bags including security bags ) manufactured by utilizing modern state-of-the-art machineries. We are certified producer from SASO – Saudi Arabia & ESMA – United Arab Emirates for Oxo- Bio Degradable products like Shrink Film, Stretch Film, Shopping Bags, Food Contact Bags & Garbage Bags.

We are certified producer from SASO – Saudi Arabia & ESMA – United Arab Emirates for Oxo- Bio Degradable products like Shrink Film, Stretch Film, Shopping Bags, Food Contact Bags & Garbage Bags.

We also undertake new product development by providing technical support for any new requirements for our customers.

Injection Moulding

Injection molding is a process in which a thermoplastic polymer is heated above its melting point, resulting in the conversion of the solid polymer to a molten fluid with a reasonably low viscosity. This melt is mechanically forced, that is, injected, into a mold in the shape of the desired final object.

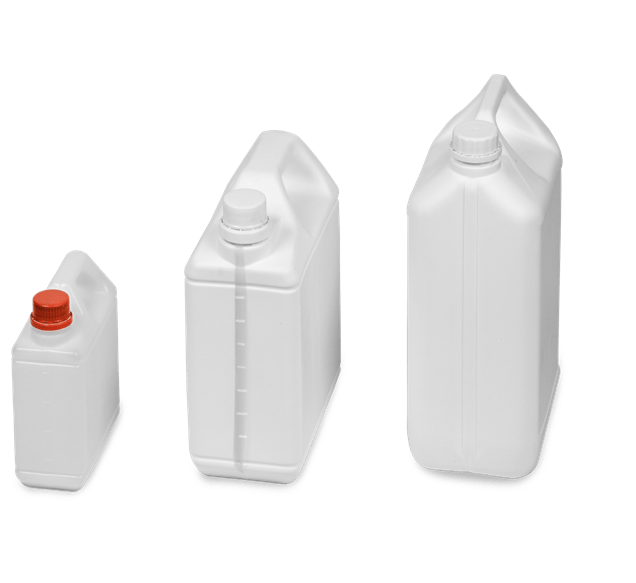

Blow Moulding

Blow molding is the forming of a hollow object by inflating or blowing a thermoplastic molten tube (parison) in the shape of a mold cavity.

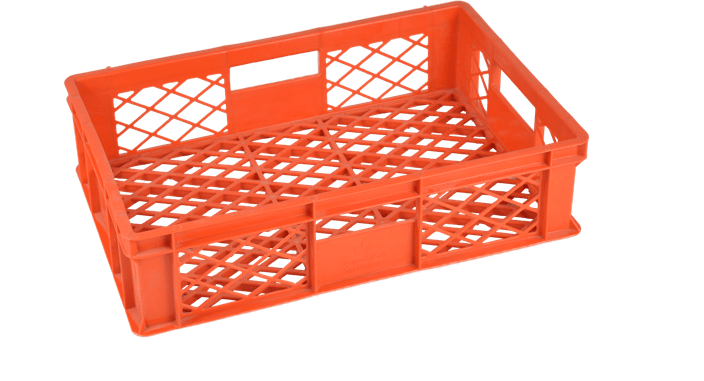

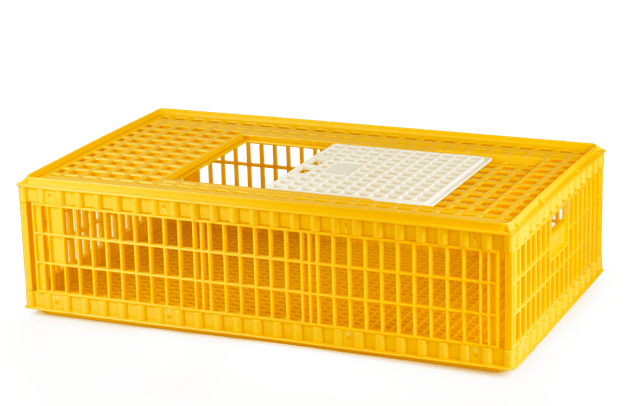

Plastic Crates

Plastic crates are mostly made of high density polyethylene (HDPE) or polypropylene (PP). Polyethylene has a higher impact strength and a very low degradation by ultraviolet radiation, while polypropylene has a better scratch resistance.

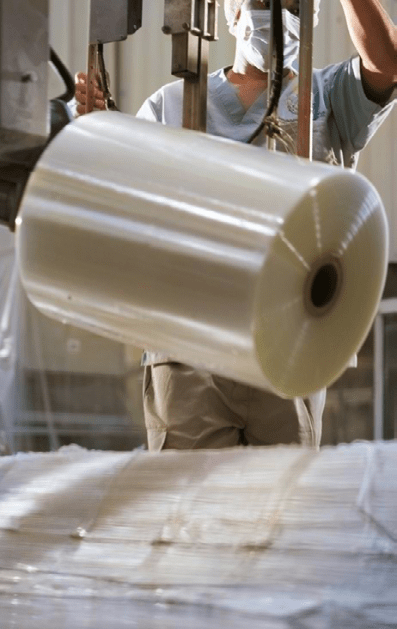

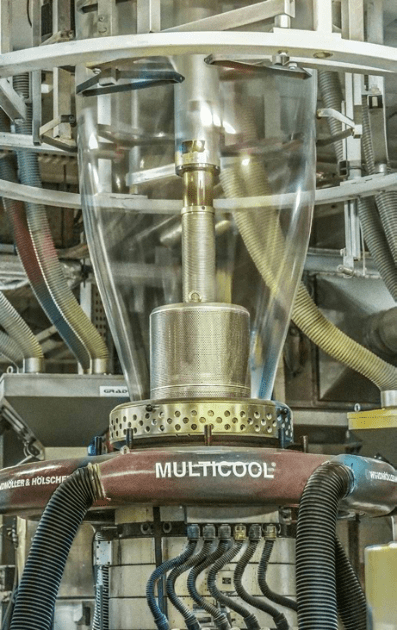

Blow Film

Blow molding is the forming of a hollow object by inflating or blowing a thermoplastic molten tube (parison) in the shape of a mold cavity.

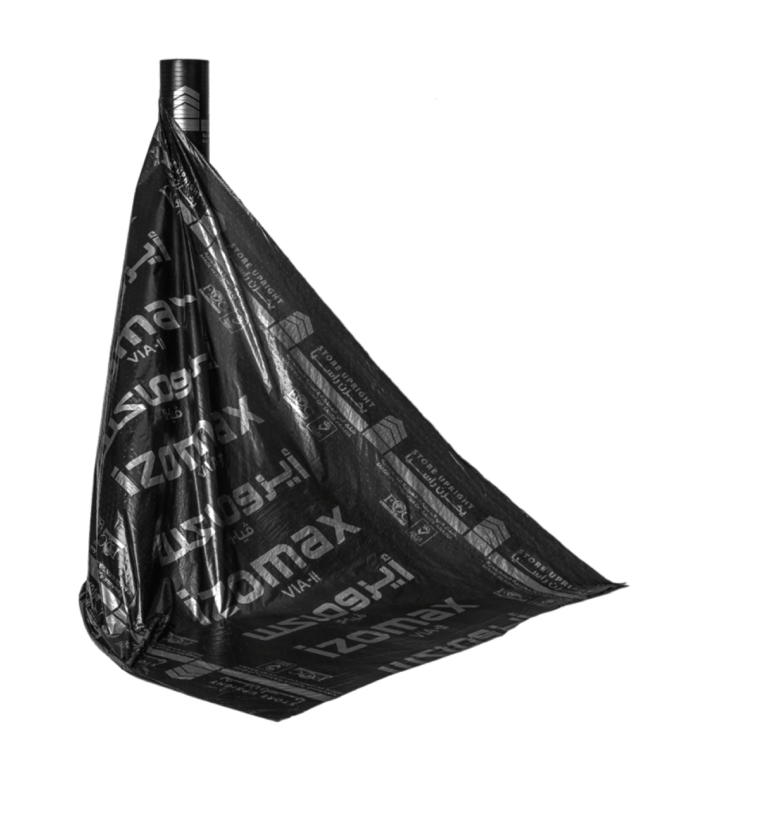

Stretch Film

Injection molding is a process in which a thermoplastic polymer is heated above its melting point, resulting in the conversion of the solid polymer to a molten fluid with a reasonably low viscosity. This melt is mechanically forced, that is, injected, into a mold in the shape of the desired final object.